Engineering enzymes for plastic degradation, machine learning miracle or evolutionary naivety?

We and others have had great success in improving the functionality of plastic-degrading enzymes using machine learning algorithms. Enzymes such as FAST-PETase and TurboPETase can completely depolymerize a wide variety of post-consumer plastics, with activity and thermostability properties which far exceed their wildtype scaffolds (Cui et al., 2024; Lu et al., 2022). These gains in enzyme performance have enabled significant improvements in PET hydrolysis and produced enzymes that are lending credence to the possibility of economical enzyme-based recycling and upcycling (“Enzymatic recycling,” 2025). Given the often-poor hit rates that arise from machine learning approaches to protein engineering, why have plastic-degrading enzymes been so amenable to this approach?

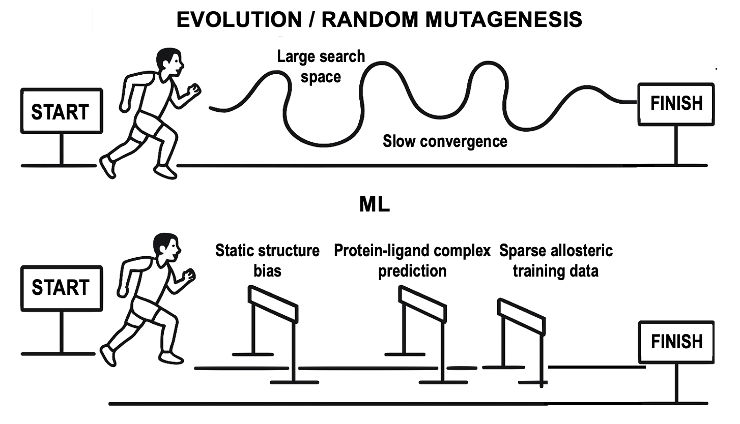

It likely stems in part from the evolutionary naivete of the proteins themselves. Plastic-degrading enzymes have only recently been discovered in part because plastics themselves are a newcomer on the evolutionary timeline, with the most well degraded plastics, PET and nylon, only having been developed in the 1930s and 1940s (Gomollón-Bel, 2016). Thus, the improvements in the performance of ML-engineered enzymes may be due to the fact that evolution has only had 70-80 years to optimize plastic degradation, in comparison to the millions to billions of years of optimization that has occurred with other hydrolases, such as proteinases and cutinases (from which many of the plastic-degrading enzymes seem to be derived). Since most protein engineering machine learning approaches are trained on the vast set of proteins that have undergone millions to billions of years of evolutionary optimization, it is perhaps not surprising that this data can be used to ‘accelerate’ the evolution of plastic-degrading enzymes, albeit in silico rather than in nature. The ML algorithms are essentially engineering within the bounds of what the databases provide: the wild-type sequences, structures, and functions of proteins (Yang et al., 2024). But in the case of plastic-degrading enzymes, there is no wild-type per se, because the functions are still just beginning to evolve. Thus, machine learning platforms can ‘accelerate’ evolution of plastic-degrading enzymes by relying on what they know of the evolution of all other enzymes.

Related to this insight is another evolutionary lemma, which is that evolution often moves from specialist à generalist à specialist (Kosonocky & Ellington, 2023). The ‘tween plastic-degrading enzymes are only just separating themselves from their parents, with PETases being a more generalist version of cutinases, and nylon hydrolases being (even more) generalist versions of N-terminal nucleophile hydrolases, whose substrate specificity is also quite broad. Now that the enzymes are growing up to specialize on the new xenobiotics they’re encountering, there are many available mutations that can help them out, while likely reducing the range of substrates they can cleave.

At the root, plastics are xenobiotics, human-made compounds, and thus it should not be surprising that despite the otherwise advanced timelines of bacterial evolution the genesis of new enzymes is only beginning. Irrespective of evolutionary rationales, machine learning should prove especially useful for creating and improving enzymes that can transform xenobiotic compounds, and we anticipate that the burst of research activity in engineering these enzymes will continue to accelerate, especially as tools enabling increased experimentation and participation become democratized. Beyond industrial interest and funding, contests such as the Align Foundation’s PETase engineering should further enable the rapid development of enzymes for a whole host of problems, with the success of the project possibly marking a new model for community driven enzyme development.

Cui, Y., Chen, Y., Sun, J., Zhu, T., Pang, H., Li, C., Geng, W.-C., & Wu, B. (2024). Computational redesign of a hydrolase for nearly complete PET depolymerization at industrially relevant high-solids loading. Nature Communications, 15(1), 1417. https://doi.org/10.1038/s41467-024-45662-9

Enzymatic recycling. (2025). Carbios. https://www.carbios.com/en/enzymatic-recycling/

Gomollón-Bel, F. (n.d.). Polyethylene terephthalate. Chemistry World. Retrieved August 12, 2025, from https://www.chemistryworld.com/podcasts/polyethylene-terephthalate/1017555.article

Kosonocky, C. W., & Ellington, A. D. (2023). Evolving to Evolve, Dan Tawfik’s Insights into Protein Engineering. Biochemistry, 62(2), 145–147. https://doi.org/10.1021/acs.biochem.2c00668

Lu, H., Diaz, D. J., Czarnecki, N. J., Zhu, C., Kim, W., Shroff, R., Acosta, D. J., Alexander, B. R., Cole, H. O., Zhang, Y., Lynd, N. A., Ellington, A. D., & Alper, H. S. (2022). Machine learning-aided engineering of hydrolases for PET depolymerization. Nature 2022 604:7907, 604(7907), 662–667. https://doi.org/10.1038/s41586-022-04599-z

Yang, J., Li, F.-Z., & Arnold, F. H. (2024). Opportunities and Challenges for Machine Learning-Assisted Enzyme Engineering. ACS Central Science. https://doi.org/10.1021/acscentsci.3c01275